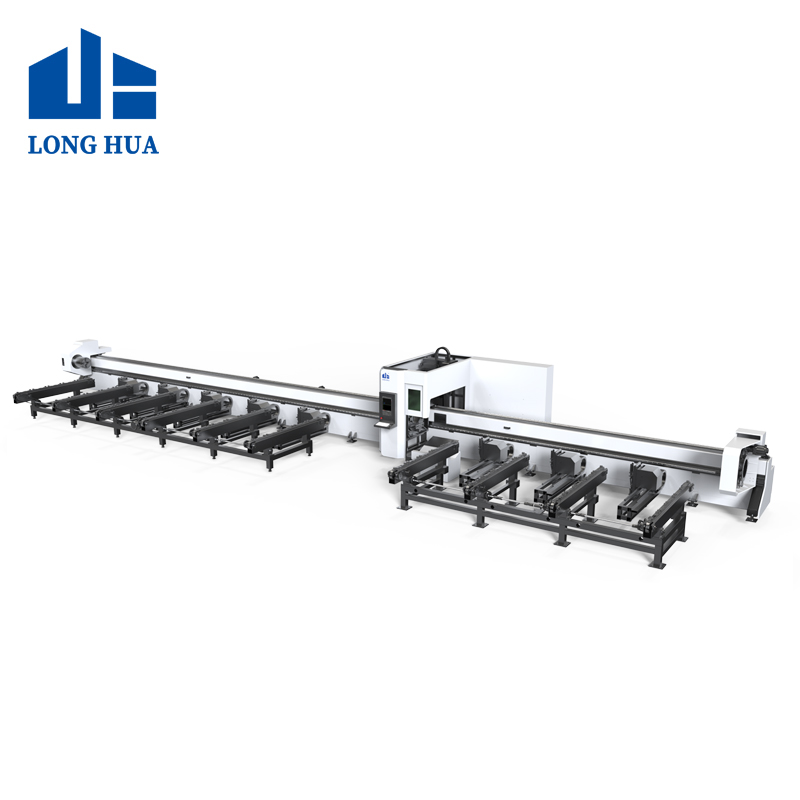

Details display

1. Heavy-duty welded bed

Heavy duty welded bed, welded through three processes, the bed is more stable and reliable;

The surface of the structure is quenched at high temperature for durability;

Precision machining by gantry milling machine, accuracy up to 0.02mm/3m.

2.Heavy duty four chucks

1.The middle unloading chuck is responsible for unloading, improving safety.

2.Solve the problem of difficult feeding of heavy pipes.

3.Realise 0 tail material

3.Professional laser head

1.Automatic focusing.

2.Modular design, easy maintenance

3.Multiple cutting angles, optional bevel cutting

4.CNC intelligent numerical control system

Adopting professional cutting software, realising automatic edge finding, automatic layout, automatic focusing and automatic cutting, convenient and efficient.

5.Inovance servo motor

❏3% increase in motor energy savings

❏Frameless permanent magnet motor direct drive with 25% higher energy efficiency

❏10% volume reduction

Data parameters

| Model | Fiber laser cutting pipe machine |

| Tube length | 6m/9m /12m |

| Maximum diameter | 10-245mm |

| Fiber power | 1000w/1500w/2000w/3000w/4000w/6000w |

| Laser length | 1064nm |

| Beam quality | <0.373mrad |

| Cutting accuracy | ± 0.05mm |

| Repeated positioning accuracy | ± 0.03mm |

| Maximum operation speed | 40 meters/minute |

| The cutting speed | Depends on the material |

| Auxiliary gas | Auxiliary gas air, oxygen, nitrogen |

| Position Type | red dot |

| Working Voltage | 380V/50Hz |

Sample display

Reviews

There are no reviews yet.