Details display

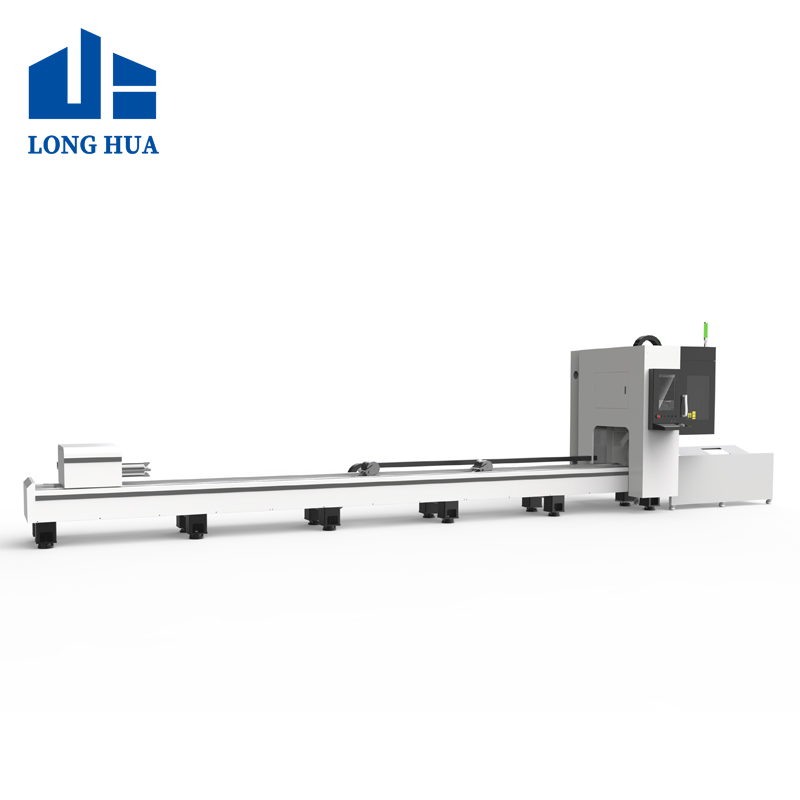

1. Heavy-duty welded bed

Heavy duty welded bed, welded through three processes, the bed is more stable and reliable;

The surface of the structure is quenched at high temperature for durability;

Precision machining by gantry milling machine, accuracy up to 0.02mm/3m.

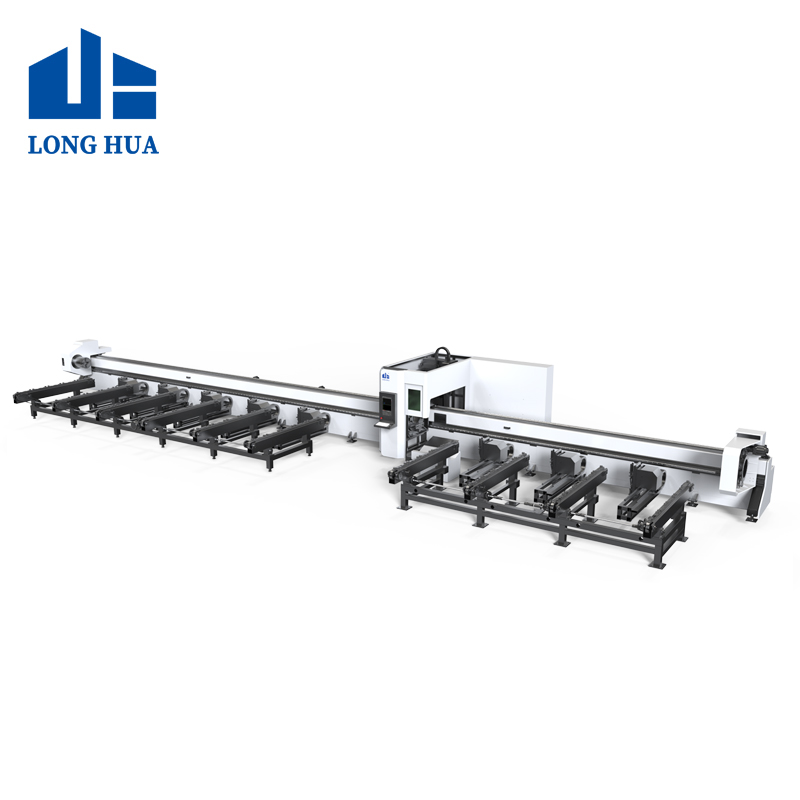

2.Heavy duty four chucks

1.The middle unloading chuck is responsible for unloading, improving safety.

2.Solve the problem of difficult feeding of heavy pipes.

3.Realise 0 tail material

3.Pneumatic chuck

Full four-jaw self-centering pneumatic chuck and propulsive cutting mode,clampingstable and non-destructive workpiece, with high centering accuracyand machiningaccuracy.lt is unnecessary to change claws while clamping20-200mm tubes.Minimizetailinglength.

4.CNC intelligent numerical control system

Adopting professional cutting software, realising automatic edge finding, automatic layout, automatic focusing and automatic cutting, convenient and efficient.

5.Dedicated laser head

Professional laser head cutting, using the world famous brand; stable and reliable technology; suitable for a variety of cutting angles;

6.Inovance servo motor

❏3% increase in motor energy savings

❏Frameless permanent magnet motor direct drive with 25% higher energy efficienc

❏10% volume reduction

Data parameters

| 1 | Model | LT-6020 |

| 2 | Power | 3000W(Optional Power:1-6kw) |

| 3 | Laser Generator | Raycus / IPG /MAX/RECI |

| 4 | Cutting speed | Max 0.8s/cut(Depending on material thickness) |

| 5 | Machine positioning accuracy | ±0.03mm |

| 6 | Machine idle speed | 120m/min |

| 7 | Maximum acceleration | 1.0G |

| 8 | Electricity demand | 380V 50Hz(customizable) |

| 9 | Machine Warranty | 3 years |

| 10 | Clamping Range | Round tube diameter:20-220/20-350 |

| Square tube side length:20-150/20-245 |

Sample display

Reviews

There are no reviews yet.